Coatings

- Ion Assisted Deposition (IAD) process

- Advance Plasma Source (APS) plasma-ion assisted Deposition

- Anti-Reflection Coatings

- High Reflection Coatings

- Coatings on Optical Fiber

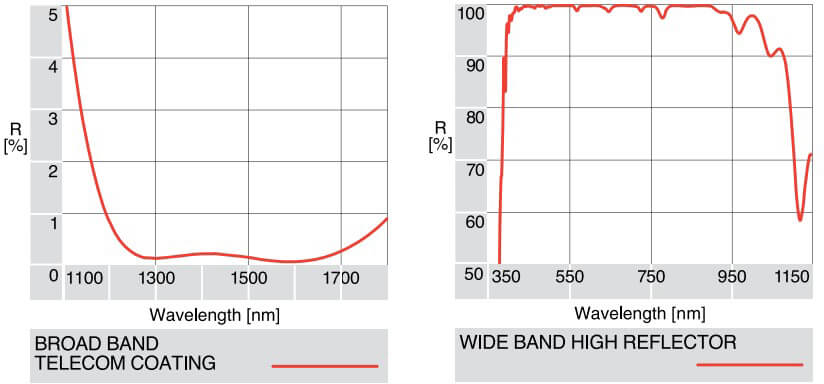

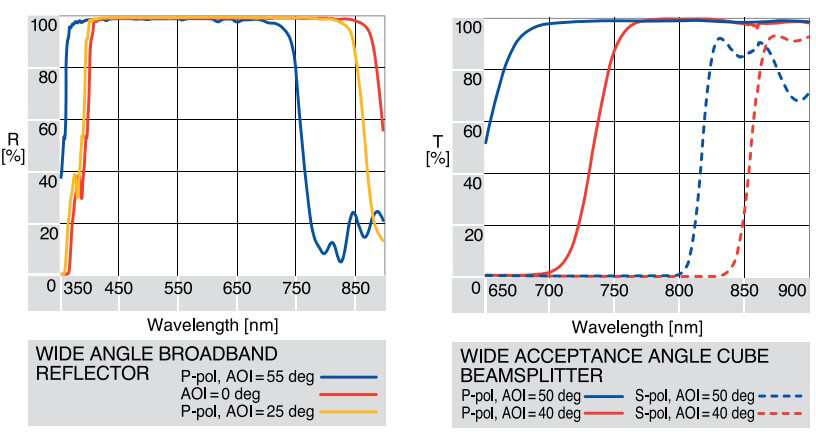

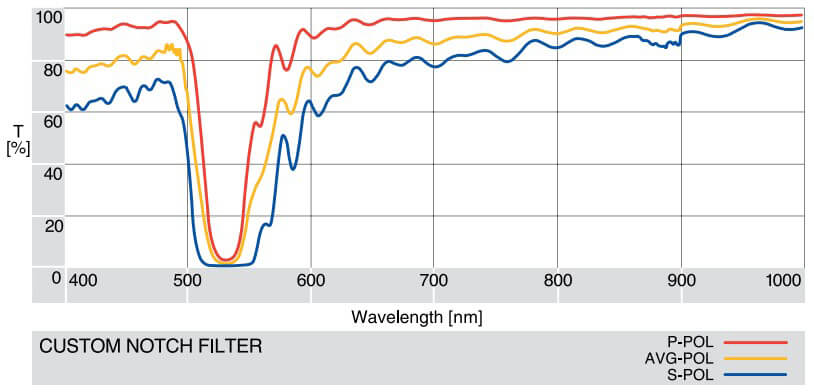

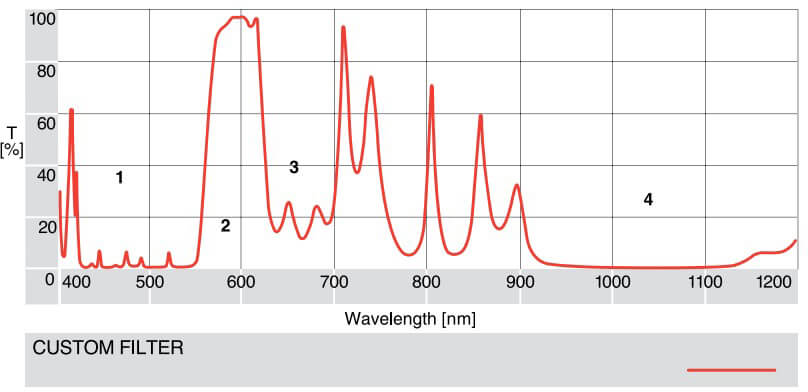

OptoSigma supplies a wide selection of optical thin film coatings. These coatings are often provided as part of the optical component but they may also be ordered separately to be applied to an uncoated element. For example, it is possible to apply an AntiReflection coating to any uncoated lenses, windows or optical fibers. Also reflecting coatings may be applied to uncoated substrates to form mirrors or partial reflectors. To make this process simple we have listed some of our most common standard coatings. To order you simply append the coating suffix to the base part number and specify the surfaces to be coated. If you don’t find the exact coating you need please ask us to provide you with a custom solution. Our coating engineers will use the latest design software and production techniques to provide you with the coating you require.

Optical thin film coatings are used to control the intensity, wavelength selection and polarization characteristics of incident electro-magnetic radiation. For laser and precision optical applications the quality of the coating is critical. Coatings must be precise as well as durable and damage resistant. OptoSigma’s advanced IAD and advanced plasm source (APS) coating facility in Santa Ana, California is able to supply high performance laser coatings covering the optical spectrum from 190 to 3000nm.

Anti-Reflection Coatings

- Lenses

- Windows

- Optical Fiber Endfacesr

We offer a wide range of Anti-Reflection coatings which may be applied to any of our glass or fused silica lenses or windows to reduce reflection losses. Through use of our Ion Assisted Deposition (IAD) process we also specialize in AR coatings on optical fiber endfaces. Low temperature IAD coatings may be applied to most fiber endface terminations. Pre and post coating inspection is performed in our dedicated facility to ensure high quality. Our “Super-V” Coatings represent the ultimate in low reflection coatings (R<0.1%) for narrowband applications. We also offer laser line V Coatings, Broadband Multilayer AR Coatings, Multiband AR Coatings, Telecom AR Coatings and Single Layer AR MgF2 Coatings. Standard coatings may be ordered by simply appending a coating suffix to the product number and specifying the number of sides to be coated. For more complex requirements we suggest that you call - our applications engineers will be pleased to advise you on the best coating for your needs. Standard Anti-Reflection coatings are listed in the following table.